Optimize Your Workflow with Collaborative Robots

The need for adaptable and efficient automation continues to grow across industries. Collaborative robots (cobots) boost productivity and safety by working directly alongside your team, taking on repetitive tasks without interrupting workflows.

At Clayton Controls, we offer expert solutions to help you fully harness the power of cobots, with scalable options for tasks such as machine tending, assembly, and more. Whether you’re optimizing existing operations or starting a new project, cobots provide rapid ROI and long-lasting advantages.

How Cobots Can Revolutionize Your Operations

Introducing Your Most Dependable Production Partner

A cobot is an advanced robot designed to work seamlessly alongside people. Unlike traditional industrial robots that require safety barriers, cobots are built for direct collaboration on the shop floor. They are easy to use, highly adaptable, and ideal for tasks that are repetitive, physically demanding, or hazardous for human workers.

Cobots are transforming industries by tackling critical operational challenges. From rising labor costs to heightened safety concerns, cobots enable businesses to increase productivity, improve safety, and enhance efficiency—allowing you to achieve more with fewer resources.

Unlock the ROI Benefits of Cobots

By integrating cobots, businesses enhance their processes while seeing substantial ROI. The initial investment in cobots pays off quickly by cutting labor costs, reducing downtime, and boosting throughput.

Reduce Labor Costs

Quick Deployment, Fast ROI

Flexibility on the Floor

Workplace Safety

Boost Efficiency & Throughput

Empower Your Workforce

Calculate Your Cobot Cost and Payback Period in Minutes

Harness the Power of Cobots Across Industries

Cobots seamlessly combine manual labor and full automation, providing a flexible solution for businesses dealing with challenges such as labor shortages, rising costs, and maintaining quality consistency. They offer precision, scalability, and minimal disruption, enhancing efficiency and empowering your team across diverse applications.

Explore key cobot applications that can optimize and streamline your operations.

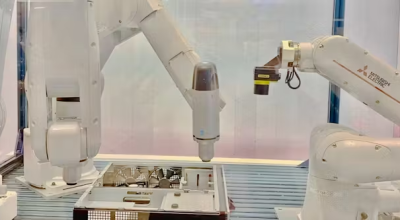

Machine Tending

Cobots automate the loading and unloading of machines like CNCs and presses, boosting efficiency and minimizing human error and operator fatigue.

Palletizing

Cobots simplify palletizing by efficiently stacking products or materials onto pallets, enhancing consistency and reducing manual labor in high-volume operations.

Pick and Place

Cobots excel in precise pick-and-place tasks, swiftly and accurately moving components or products to various locations on the production floor.

Assembly

Cobots assist assembly lines by performing repetitive tasks like part assembly and screwdriving with high precision, increasing speed and minimizing errors.

Hazardous Environments - C1D1

Cobots are perfect for hazardous environments, like C1D1 areas, where they can safely manage dangerous materials or processes, minimizing risk to human workers.

Welding

Cobots handle welding tasks with precision, delivering consistent, high-quality welds for spot and arc welding, especially in small-batch and custom production runs.

Lab Automation

Cobots automate repetitive laboratory tasks like sample preparation and testing, enhancing efficiency, consistency, and accuracy, while allowing staff to focus on more complex work.

Inspection

Cobots with vision systems and sensors inspect products for defects or quality issues, ensuring consistent quality control and minimizing the risk of human error.

Industry-Leading Cobots — Powered by Clayton Controls

Clayton Controls is proud to be a trusted distributor of some of the world’s leading collaborative robots. By partnering with top brands like Universal Robots and Mitsubishi Electric, we provide access to best-in-class cobots that meet the needs of every application and budget.

We help manufacturers unlock the full potential of these cobots with comprehensive turnkey solutions. From design and integration to ongoing support, Clayton Controls ensures a smooth implementation, minimizing downtime and maximizing efficiency.

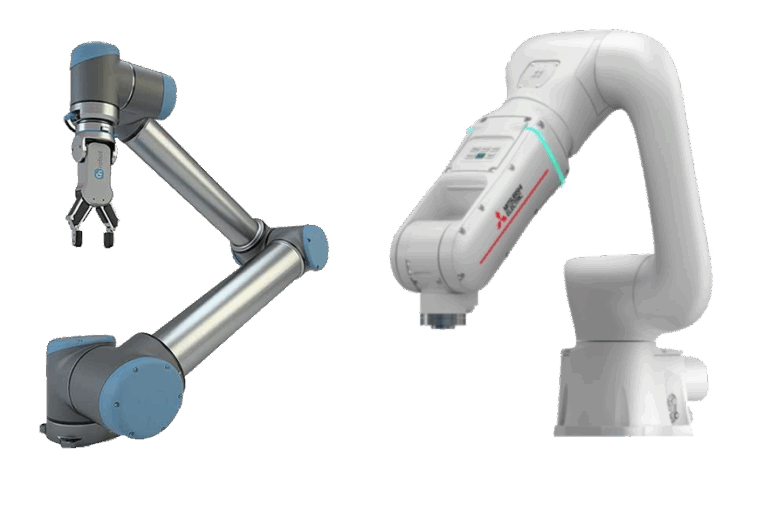

Universal Robots

Universal Robots (UR) offers flexible, easy-to-program collaborative robots that are designed to enhance productivity and automate repetitive tasks in a wide range of industries.

Mitsubishi Electric Automation

Discover precision and dependability with Mitsubishi Electric’s cobots, designed for high-speed performance and safe, collaborative operations across a variety of industrial applications.

New legislation just made robotics the hottest investment!

On July 4, 2025, Congress passed H.R.1 (Public Law 119-21), reinstating 100% first-year bonus depreciation for qualified production equipment. That means robotic systems - including cobots - can now be fully deducted in year one, accelerating ROI more than ever.

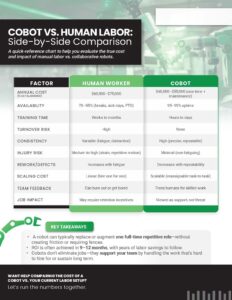

Cobot Knowledge Hub

Stay informed with the latest advancements and best practices in collaborative robot. Click on the resource to start your download.

FAQ: Everything You Need to Know About Cobots

A cobot is designed to work directly with humans, without the need for physical barriers. It’s typically smaller, more intuitive to program, and more cost-effective than traditional industrial robots.

Yes, cobots are engineered with safety as a priority. They include force-limiting sensors, emergency stop functions, and can slow down or stop if they detect a person nearby, ensuring a safe working environment.

Consider the tasks the cobot will perform, the weight and reach requirements, the level of automation needed, and your budget to select the most suitable cobot for your operations.

Most cobot systems are deployed in just a few days, not months. Clayton Controls’ integration team provides full setup and training, ensuring a quick start with minimal downtime.

Cobots are used across many industries, including manufacturing, packaging, metalworking, electronics, food and beverage, and more—anywhere efficiency and safety are priorities.

Yes, cobots are portable and can easily be reprogrammed for new tasks, making them perfect for dynamic production environments where flexibility is key.

Talk To One Of Our Experts!

Powered by Expertise. Driven by Solutions.

Clayton Controls brings decades of automation expertise and trusted manufacturer partnerships to every solutions we deliver. Let’s talk about your next project.

Need to speak with someone now? Call us.

800.235.4411