Dorner is a Leader in the design, applications, manufacturing, and integration of conveyor systems. Companies from over 1,200 different industries worldwide turn to Dorner to achieve improved efficiency, productivity, and a positive ROI. Dorner offers the broadest range of unit handling conveyors in the world, moving everything from machined parts to raw food products.

Have you tried Dorner's Conveyor Configurator?

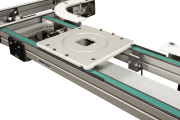

The 1100 Series conveyorplatform is the industry’s smallest conveyor with a compact design featuring a 3/4″ frame height. This low profile enables the conveyor to fit into the tightest of spaces, freeing up valuable machine or worker space.

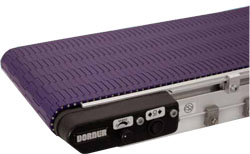

2200 Series low profile, high performance fabric and modular belt conveyors feature a high speed nose bar transfer option, a durable single piece frame design, universal T-slots, and a wide range of belting and guiding options. The 2200 Series Line is engineered for small to medium sized parts, precision applications and flexible layouts.

Featuring an increased weight rating and extended maximum width, the 2700 Series Medium Duty is designed for medium load conveyance in material handling and eCommerce applications. This conveyor includes v-guiding and precision belt tracking to eliminate belt sway even when the conveyor is wider than it is long.

The lightweight aluminum frame design makes the 2700 ideal for AGV/AMR applications and can carry a heavier payload without weighing down the robot. The increased width and low profile mounting also allow this conveyor to fit into smaller spaces while maintaining the strength needed to convey larger products.

3200 Series heavy duty, low maintenance conveyors that are ideal for medium to heavy sized parts, precision applications, bulk handling and both automated and manual assembly. Available in both fabric and modular belts, 3200 Series Conveyors are designed for high speeds, long runs and up to 4 curves per conveyor.

The Heavy Duty 3200 Series conveyor is available i3 formats: Flat Belt End Drive, Cleated Belt End Drive, and Center Drive models.

Dorner’s line of sanitary conveyors are designed to improve your food safety. With Dorner’s hygienically designed conveyors, you can have confidence in your food handling equipment and less worry about product quality. Features such as removable wear strips, belt lifters and frame cut outs allow fast access to the conveyor frame, meaning these conveyors clean up two times faster than the competition.

The 7X series of conveyors, also known as our AquaGard and AquaPruf platforms, take food handling conveyors to a whole new level. Designed for fast and effective sanitation and protection from contamination, 7X line provides the same Dorner quality and flexible designs as all our systems.

Dorner is also proud to offer the only USDA certified conveyors in the industry: the AquaPruf 7400 Ultimate and 7600 Ultimate. They are the only modular conveyor on the agency’s list of accepted equipment for the meat and poultry industry.

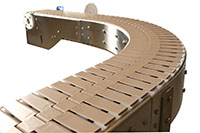

Dorner’s Pallet System conveyors simplify product flow and control with features such as a unique pin tracking system, industry compatible pallet sizes and innovative modules. 2200 Series Precision Move Pallet System conveyor and the SmartFlex Pallet Systems are advanced in pallet traffic management and are specifically designed to increase efficiency, reduce downtime in automation processes, and provide the accurate conveying.

Dorner's precision edge roller pallet and tray handling conveyors provide efficient, non-contact zoning for medium & heavy load assembly automation applications. They feature a clean, open roller design and are ISO Class 4 approved for cleanrooms.

The ERT 250 is built for cleanroom applications such as medical product and device manufacturing, assembly, and packaging, as well as medium-large heavy load assembly automation applications.

ERT 250 Edge Roller Information

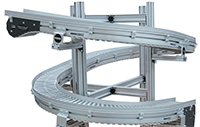

When floor space is tight and applications call for product to be moved up or down, Dorner’s trio of SmartFlex curve conveyors are the perfect answer.

The SmartFlex Helical Curve, Spiral, and Alpine conveyorsgreatly expand the capabilities of Dorner’s SmartFlex line by giving customers the ability to move product up or down and around equipment to accommodate tight spaces.

Dorner’s SmartFlex line is a flexible conveyor platform that reduces costs, saves time and offers simple configuration and acquisition options to Dorner’s customers within the packaging, medical, health and beauty, industrial automation and electronic industries.

In today’s fast-paced society having access to ready-made food is an important convenience. With an increase in demand there is an increased need for production. One way to maximize productivity is to have food moving along a conveyor with employees adding ingredients as the product passes their station. Using a conveyor assembly line for ready-to-eat food is a more streamlined process because each employee is only in charge of one ingredient instead of having to make the entire product.

Using an AquaPruf series conveyor from Dorner is a great way to move product along while maintaining sanitary requirements. The AquaPruf series is designed with food sanitation requirements in mind.

The AquaGard line of conveyors is designed for a wide variety of applications in sanitary environments that require conveyor wipe-downs.

Ready-to-Eat Conveyor Information

Clayton Controls is a Dorner distributor in California. We offer technical support to help our customers solve their applications.

Copyright © 2022 · All Rights Reserved ·

Clayton Controls Inc. - Headquarters, 2865 Pullman Street, Santa Ana, CA 92705 Tel: 800-235-4411

Campbell Office, 1671 Dell Ave., Suite 110, Campbell, CA 95008 Tel: 800-341-4445

Central California Office, 109 Fox Street, Lemoore, CA 93245 Tel: 800-235-4411

Arizona/Southern Nevada Office, 4343 N. Scottsdale Road, Suite 150, Scottsdale, AZ 85252 Tel: 480-673-3327